strength in depth

Why Lankhorst offshore?

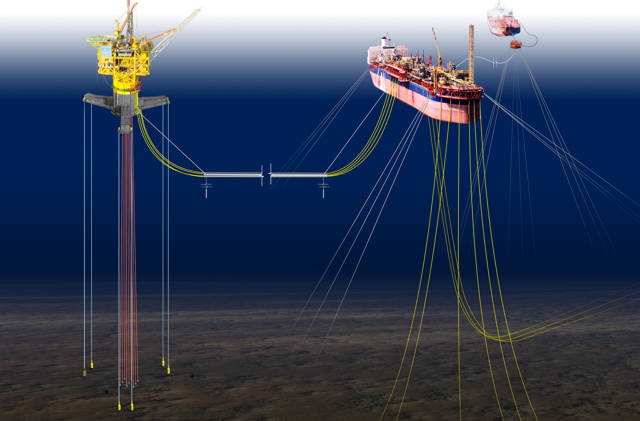

A comprehensive designed package is offered, tailored to suit individual location requirements and water temperatures, concentrated on operational performance, reliability, safety and ontime delivery.

We can supply a full range of products manufactured and supplied in strict accordance with the OCIMF 2000 “Guidelines for the Purchasing and Testing of SPM Hawsers” and OCIMF 2018 “Guidelines for Offshore Tanker Operations”.

Our technical department is committed to ongoing testing, development and optimisation of rope designs.

Our sales engineering support team provides invaluable technical support to all our customers with recommendations given at first hand to ensure the most cost effective solutions to in-service problems.

The latest Computer Aided Design and DeskTop Publishing technology allow us to produce “As Built” drawings, and fully documented manuals for any mooring system.

In addition to a fully equipped chemical laboratory for forensic analyses, we have direct access to in-house computer controlled testing equipment to evaluate, reverse bend, elongation, abrasion, tensile loading of yarn and fibre ropes with a load capacity up to 1,200 tonnes.

For more information

single point mooring+351 229 619 200spm@lankhorstoffshore.com