Lankhorst Offshore has manufactured and supplied mooring lines for major floating offshore energy projects including:

- Windfloat Atlantic

- Kincardine

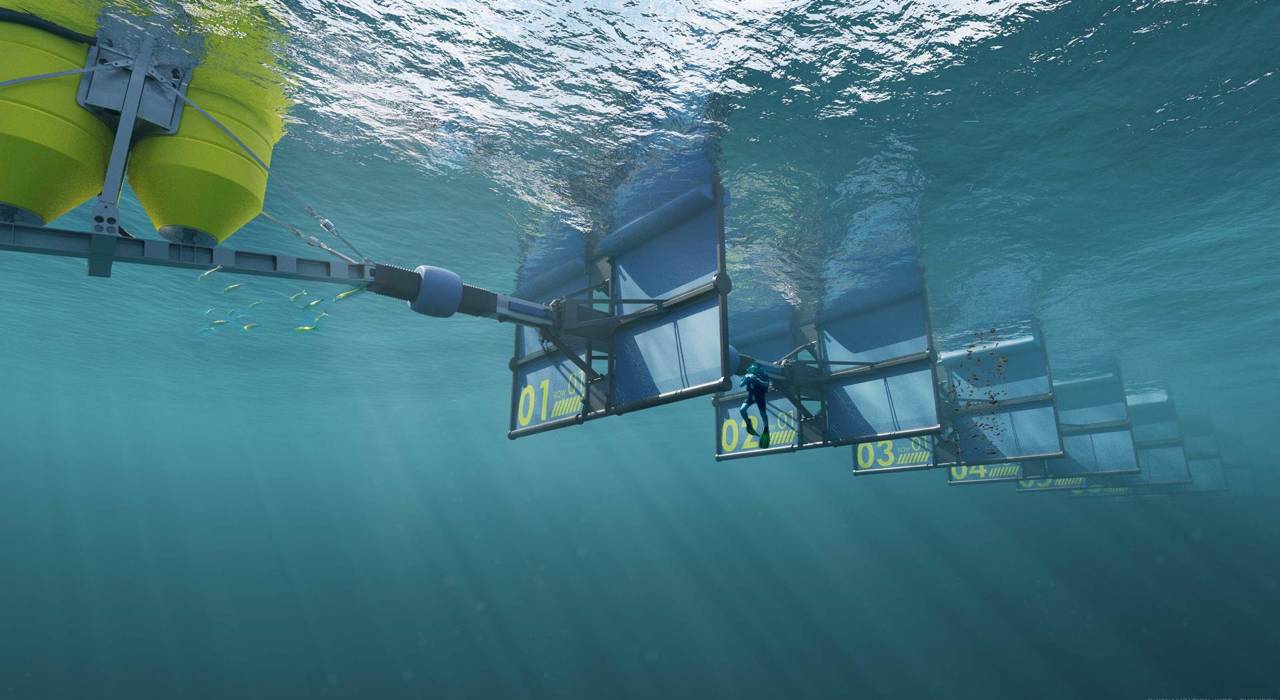

- Wave Piston

- TetraSpar Demo

Offshore Wind Turbine Mooring

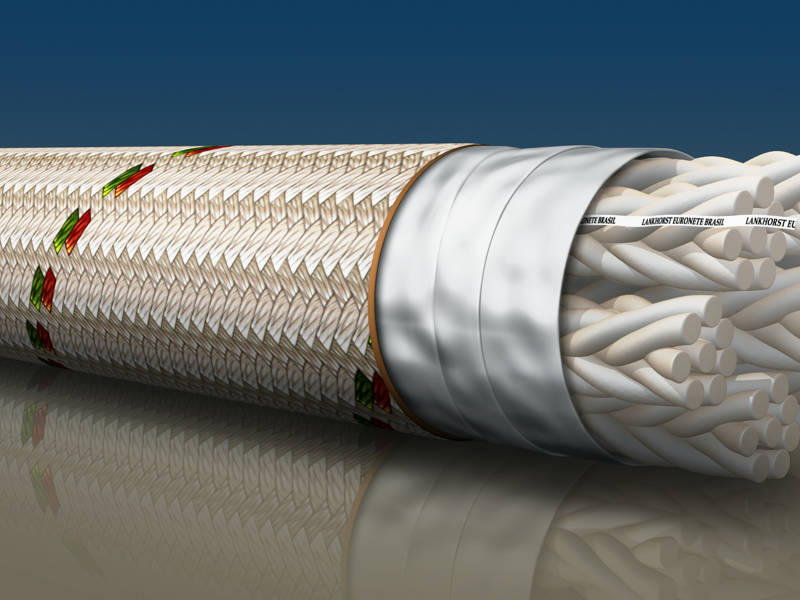

Lankhorst Offshore has extensive rope engineering design, manufacturing and testing facilities enabling the development of project-specific ropes best suited to the prevailing offshore mooring conditions, and mooring line configuration.

Proven fibre ropes for floating offshore wind turbines offering excellent mooring characteristics, with reduced pretension requirements, leading to lower costs of installation.

Secure outside storage areas for finished product are available to clients at both our Portugal (LEP) and Brasil (LEB) facilities. At LEP there is 4,000m2 with further storage available at the nearby port of Viana do Castelo. At LEB there is 1,200m2 with an additional 42,000m2 at our transport carrier partner located 1.5km from our factory in the same industrial park.