strength in depth

Why Lankhorst Offshore?

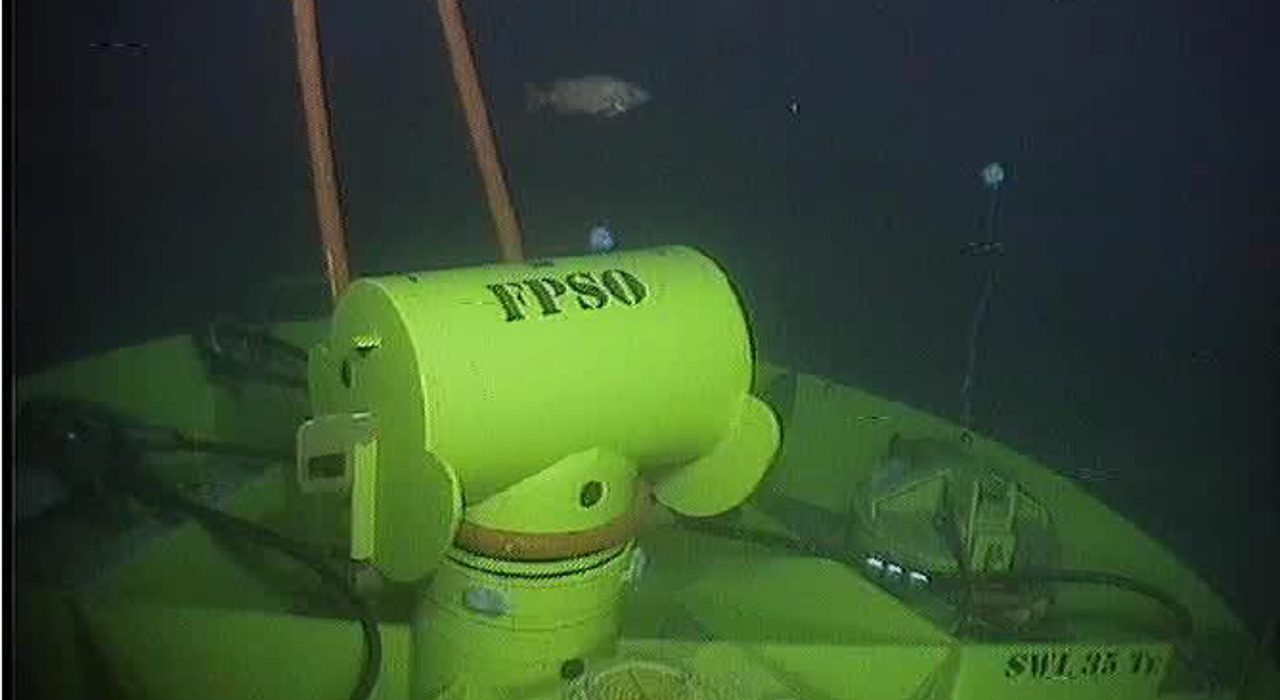

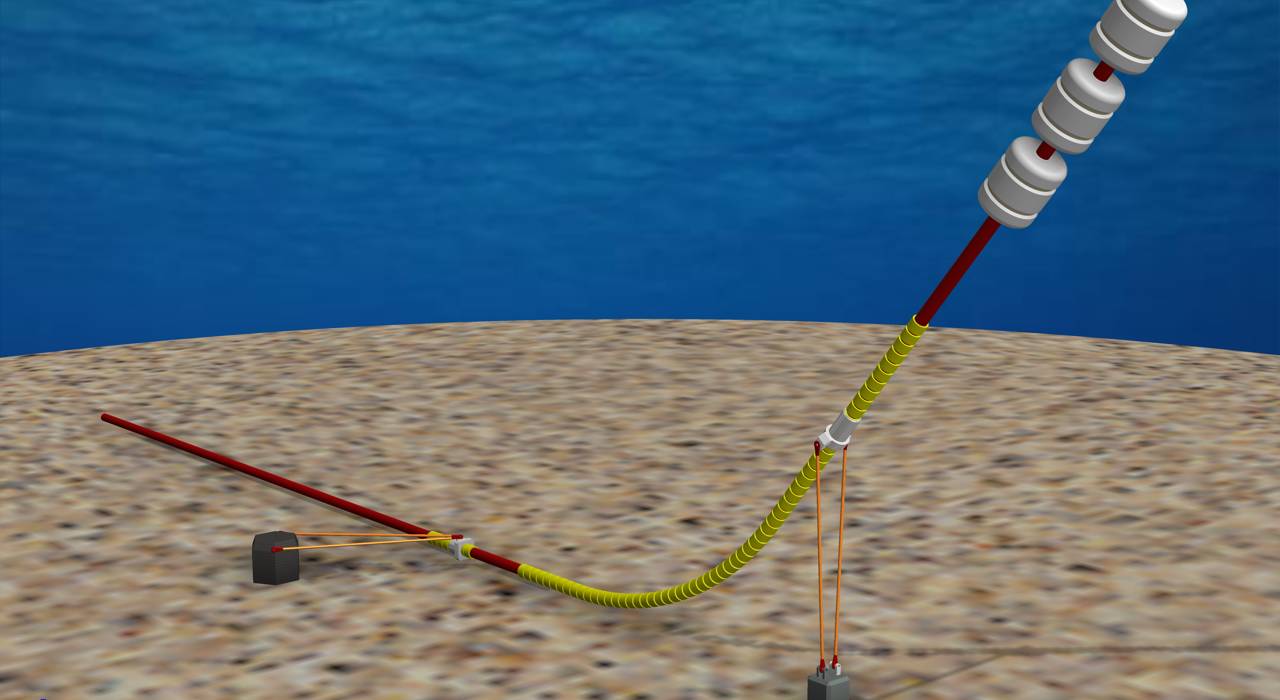

Lankhorst Offshore synthetic fibre tethers have a proven track in demanding offshore applications such as riser and umbilical tethers and mooring mid-water arches.

The use of synthetic fibre tethers such as the LANKO®FORCE and GAMA98® with Dyneema® has significant performance advantages over chain and steel wire tethers. In addition to being lighter and with almost neutral buoyancy, synthetic fibre tethers offer reduced cost of buoyancy elements, no corrosion, no fatigue issues and easy system installation.

LANKO®FORCE and GAMA98® Dyneema® ropes has the same (or lower) diameter as a conventional steel wire rope yet the corresponding weight is 7 times lower. In water, it has negligible weight. The stiffness is similar to steel wire.

Filter elements are included between jacket and sub-rope cores. They are effective in filtering out particles greater than 5 microns whilst allowing free flooding of the rope.

Under constant loading, the LANKO®FORCE and GAMA98® Dyneema® rope can show an irreversible deformation that will depend on the time, load and temperature. For 25 years and for normal water temperatures, the irreversible elongation (creep) is null. The fatigue life of synthetic ropes is typically quoted as being at least 80 decades superior to steel wire rope.

Lankhorst Offshore has a dedicated rope test machine for loads up to 1,200 tonnes. It can also conduct tension-tension fatigue testing of ropes to any fatigue regime specified by clients and certified verification authorities. The test facility can be used for proof loading and length verification of tethers up to 25m in accordance with various industry standards such as ABS, BV and DNV GL rules.

For more information

synthetic tethers+351 229 619 200synthetictethers@lankhorstoffshore.com