strength in depth

Why Lankhorst offshore?

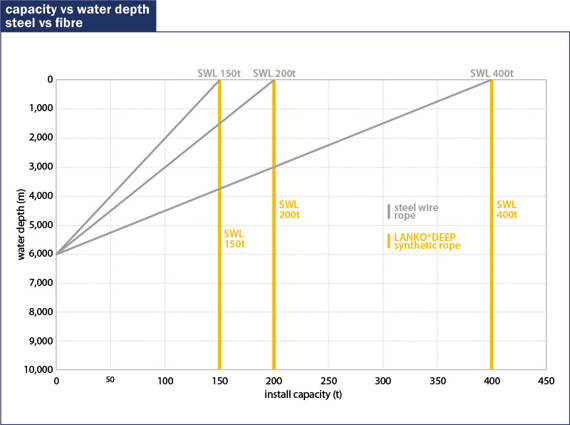

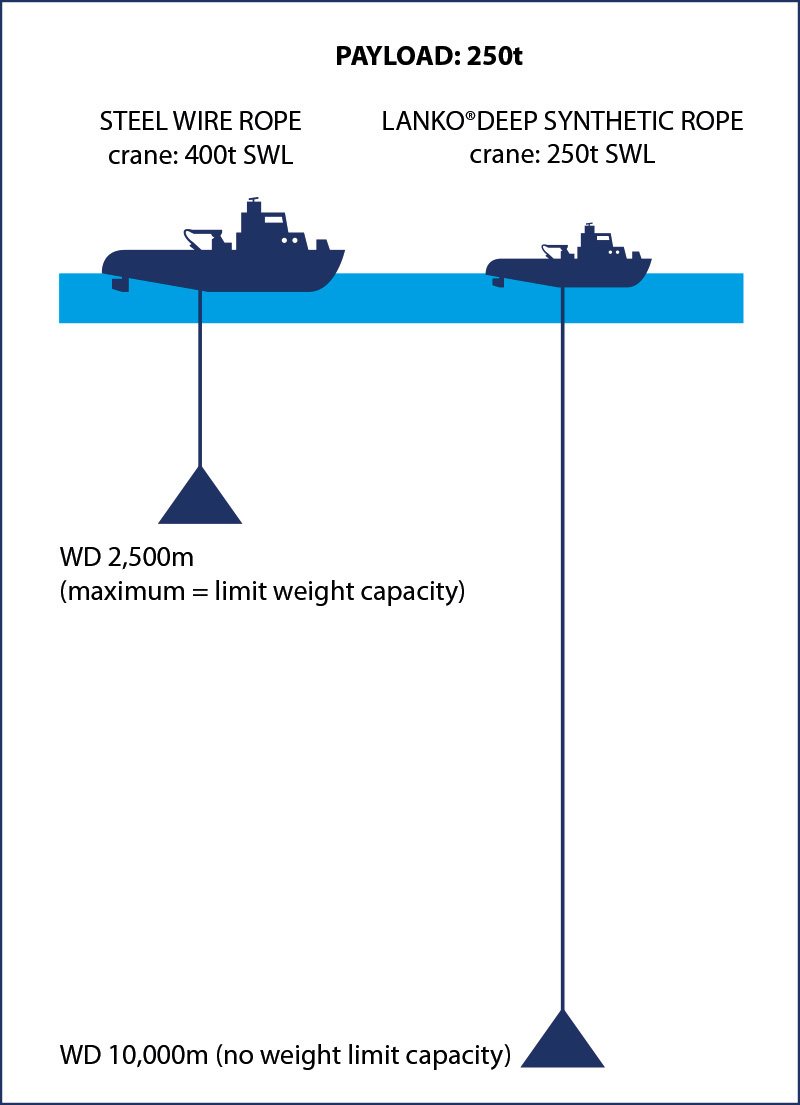

The weight of steel wire ropes makes wire rope lifting / lowering systems both inefficient and impractical at water depths greater than 2,000m. At 3,000m, the lifting capacity is reduced by 50%; the other 50% is to support the weight of the steel wire.

The solution to optimising lift and lowering capacity is to use a Fibre Rope Deployment System (FRDS). The weight of fibre rope is much less than the steel wire rope, making

them almost neutrally buoyant when used in water and with a 100% crane capacity, irrespective of the water depth.

Lankhorst Offshore has a dedicated rope test machine for loads up to 1,200 tonnes. It can also conduct tension-tension fatigue testing of ropes to any fatigue regime specified by clients and certified verification authorities. The test facility can be used for proof loading and length verification of tethers up to 25m in accordance with various industry standards such as ABS, BV and DNV GL rules.

Our sales engineering support team provides invaluable technical support to all our customers. The latest Computer Aided Design and DeskTop Publishing technology allow us to produce “As Built” drawings, and fully documented manuals for any deepwater deployment system.

In addition to a fully equipped chemical laboratory for forensic analyses, we have direct access to in-house computer controlled testing equipment to evaluate, reverse bend, elongation, abrasion, tensile loading of yarn and fibre ropes with a load capacity up to 1,200 tonnes.

For more information

deepwater deployment+351 229 619 200dwd@lankhorstoffshore.com