Single point mooring hawsers typically manufactured from nylon (SG 1.14) will not float naturally in seawater. A hawser which sinks will foul the catenary moorings of a CALM buoy or other subsea equipment. Lankhorst Offshore has a range of flotation methods.

The integrity of the mooring hawser depends on the floats sustaining hawser buoyancy. All our floats feature a double outer layer manufactured from high abrasion resistant ballistic nylon cloth. All seams are double stitched from heavy denier yarn using a locking stitch, so yarn breakages cannot lead to an unzipping effect. The floats utilize high quality 48 kg/m3 100% closed cell polyethylene foam, and high quality eyelets exceeding Shell pull test standards. Additionally these floats can be polyurethane elastomer coated on the outside.

• Lace-on hawser float

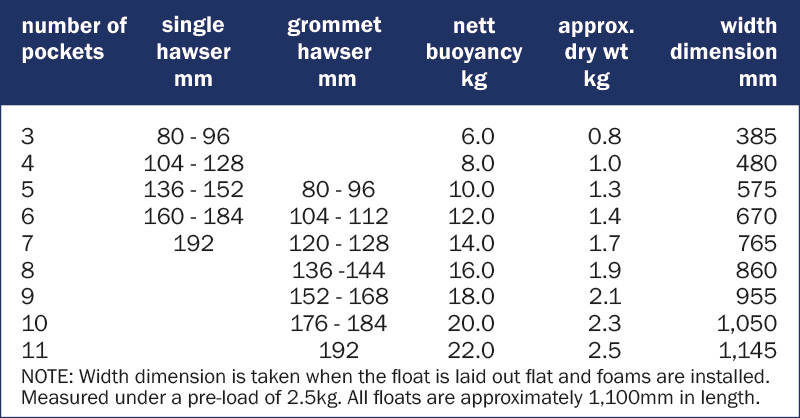

The integrity of the mooring hawser depends on the floats sustaining hawser buoyancy. All our floats feature a double outer layer manufactured from high abrasion resistant ballistic nylon cloth. All seams are double stitched from heavy denier yarn using a locking stitch, so yarn breakages cannot lead to an unzipping effect. The floats utilize high quality 48 kg/m3 100% closed cell polyethylene foam, and high quality eyelets exceeding Shell pull test standards. Additionally these floats can be polyurethane elastomer coated on the outside. See table to the right.

• Integral hawser flotation

During the lifetime of the hawser the floats tend to suffer damage and can be ripped away from the rope. Our integral flotation system overcomes these issues, and in addition offers many other operational benefits.

Mooring hawsers incorporating our integral flotation system are wrapped in closed cell buoyancy foam, ensuring sufficient reserve buoyancy is calculated into the construction to support the hawser in seawater. This is covered with an over braided jacket. Additionally this can be polyurethane elastomer coated to enhance the abrasion characteristics of the assembly.

• Tubular float

In cases where long service life with minimal maintenance is required, we recommend the use of our tubular floats. These are available in varying lengths and diameter to suit. Tubular floats are stiffer than the fibre rope, so flexing may occur at the exit points from the floats. The longer the float length, the greater the flexural concentration.

Therefore we do recommend a larger quantity of short length floats, as opposed to a smaller quantity of longer length floats.

Please ask us for detailed data sheets on the above mentioned flotation types.