CBOS – the Importance of Keeping Cool

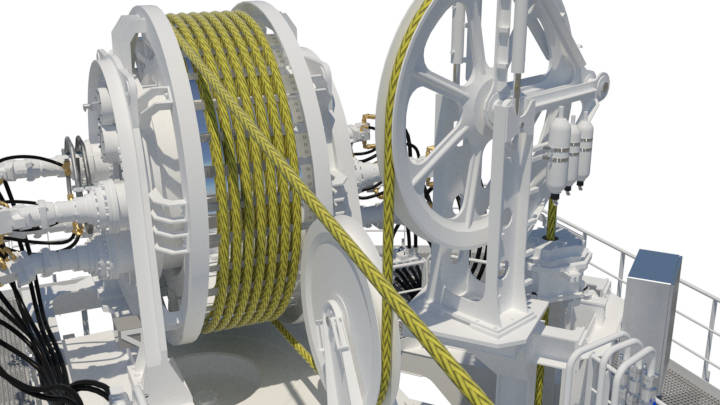

01-05-2020Cyclic rope bending over a sheave is common to many deepwater deployment and recovery (DDR) operations, as when operating with active heave compensation (AHC). "Keeping the rope cool is vital to ensuring rope performance and endurance", reports Sergio Leite, Sales Director, Deepwater Deployment, Lankhorst Offshore.

Bending a fibre rope causes internal abrasion as the fibres rub against each other and an increase in rope temperature due to the effects of friction. As every fibre has a temperature threshold were the fibre properties decline, is it essential to take measures to ensure that the temperature limit is not reached. CBOS testing allows us to do this.

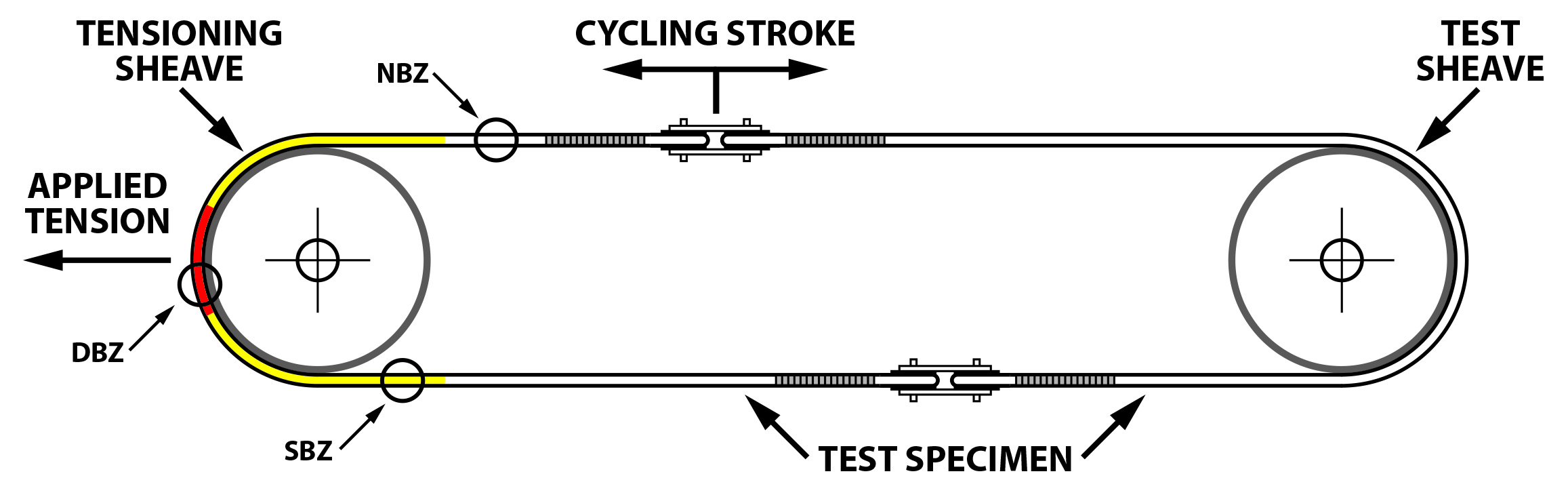

A typical CBOS test machine is:

The sheaves are customised to the rope diameter and thus replicate the actual AHC system. Testing is used to determine the load conditions and bending cycles that would result in a rope temperature increase up to the rope fibre’s temperature limit.

Temperature is measured in the Double Bend Zone (DBZ), in the Single Bend Zone (SBZ), in the None Bend Zone (NBZ) through the use of thermocouples inserted in the centre of the rope. Sheave and ambient temperature were also measured.

During the CBOS test performed in dry conditions, even with forced convection, it was evident that the operational window was only suitable for mild conditions (less tension and larger cycle times). For harsher conditions (higher load and shorter cycle time) that might be encountered during DDR the operational window was very short. Importantly it was noticed that the temperature of the rope was constantly fluctuating, never reaching the stationary state. Clearly this indicated an unacceptable level of instability as the temperature increased.

Therefore, to widen the operational window for higher loads, an effective way of removing the heat from the rope was needed.

Introducing a small quantity of water sprayed at the sheave entry (both sides) was found to be very effective in controlling and maintain the rope temperature below the limit, even under the more extreme conditions. Moreover, the water-cooled rope established a stable equilibrium temperature. This was a very positive result as the test conditions were above the limit operational conditions envisaged for a DDR system.

Deepwater Deployment and Recovery

The development and implementation of new technology is always a challenging process. The approach to CBOS testing described here has been used to develop of a synthetic fibre rope-based DDR system validate safe use and set a benchmark for future dynamic large diameter ropes.

In the next article, we report on DDR rope bending endurance and effects of abrasion.

For more information on Lankhorst Offshore deepwater deployment and recovery ropes, contact Sergio Leite, Sales Director, Deepwater Deployment, Lankhorst Offshore, email sl@lankhorstoffshore.com, and visit www.lankhorstoffshore.com.